Socket Weld and Threaded Fittings (ASME B16.11)

FORGED FITTINGS ASME B16.11

Forged vs. Buttweld Fittings

Forged fittings are used for piping systems below 2 or 4 inches in diameter (4″ for 2000#/3000# fittings, 2″ for 6000#/9000# fittings), whereas buttweld fittings are used for larger diameter piping.

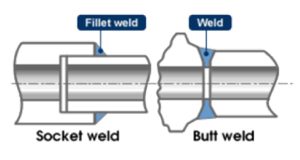

The two main types of forged fittings are the so-called socket weld fittings (which are connected to pipes by fillet welds) and threaded fittings (the pipe is screwed onto the fitting).

The ASME B16.11, MSS SP 75, MSS SP 83, MSS SP 95 specifications cover forged fittings (socket weld and threaded) to fit ASME B36.10 and ASME B36.19 carbon, alloy, stainless steel and nickel alloy pipes of small bore size.

Forged fittings are manufactured from solid blocks of steel, that are machined to obtain the final required shape within the tolerances set by the applicable specifications mentioned above. This is different from buttweld fittings, which are manufactured by cutting, bending and shaping seamless or welded steel pipes.

Forged Fittings Types

Socket weld and threaded fittings are available in multiple shapes (elbows, tees, caps, adapters, couplings, etc), sizes (bore sizes between 1/8 and 4 inches, and ratings as 2000#, 3000#, 6000#, 9000#) and material grades (the most common are ASTM A105, ASTM A350 LF1/2/3/6 for low-temperatures, ASTM 182 for corrosive, high-temperature applications). The class of the fitting represents the maximum allowed pressure that the device can withstand.

Class 3000 fittings are used for pipes in schedule 80/XS; Class 6000 for pipes Sch. 160; Class 9000 fittings for pipes with larger wall thickness (XXS).

Forged Elbow 45/90 Degrees

Forged elbows are used to change the direction of the piping system by 45 or 90 degrees. Forged elbows are manufactured according to ASME B16.11 in various material grades, either with socket weld or threaded pipe connections. A special type is the so-called “street elbow”.

Forged elbows 45 and 90 degrees, street elbow.

Forged Tee (Equal/Reducing)

Forged tees are used to branch a pipe at 90 degrees. Tees can be straight (equal) or reducing.

Forged tees ASME B16.11 are available with socket weld or threaded connections (NPT or BSP). The dimensions of forged tees are covered by the MSS SP 75 and the ASME B16.11 specifications.

Forged Lateral

Forged laterals feature a Y shape and are used to branch a pipe at 30-degrees (or different angles, according to the piping specifications).

Forged Plug (Round, Squared, Hex)

Forged plugs are available with a round, squared or hexagonal head and are used to blind pipes.

Bushings

Hexagonal bushings are manufactured in accordance with ASME B16.11 and are used to join two threaded items of a different size.

Couplings (Half, Full)

Couplings are forged fittings manufactured in accordance with ASME B16.11 and are used to join pipes.

They are available in half or full size and with socket weld or threaded connections (or a combination of the two for special piping applications).

Reducers and Reducer Inserts

Reducers are available in two main types, called 1 and 2. They are used to connect pipes and reduce the bore size.

Union

Unions are available in the male to female, female to female types, lug nut, and Rockwood design. Unions comply with the MSS SP 83 standard.

Welding Boss

SOCKET WELD VS. THREADED FITTINGS

ASME B16.11 forged fittings are available with two types of end connections, which are called “socket weld” and “threaded” (shown in the picture).

SOCKET WELD FITTINGS

Socket weld fittings are connected to pipes by fillet welds, whereas threaded fittings are screwed onto the pipe (or vice-versa).A socket weld fitting (left side) and a threaded fitting (right side).

Socket weld fittings are used for applications where strong and long-lasting connections are required. Socket weld fittings are very reliable but are time-consuming to install in a piping system (due to the heavy workload caused by welding operations on small parts).

Socket weld fittings are available in sizes from 1/8 to 4 inches and in classes between 2000# and 9000#.

The typical applications for socket weld fittings are:

- Steam

- Explosive fluids and gases

- Acids and toxic fluids

- Long service / durable installations

Fillet weld vs. Butt Weld: a butt welding connection fills the gaps between two devices, that are beveled at 30 degrees.

THREADED FITTINGS

Threaded fittings are used for less-critical piping systems, such as water distribution, fire protection, and cooling, or for low-pressure installations not subject to vibration, elongation and bending forces. Threaded pipe fittings are not suited for fluids with constantly changing temperatures, as sudden changes may crack the connection.

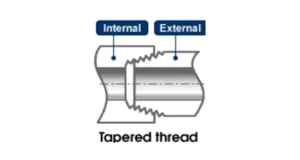

The two major types of threads are the BSP and NPT, which are not compatible one with the other:

BSP Fittings

BSP means “British Standard Pipe” and can be further divided into the BSPT (tapered) and BSPP (parallel) variations. The threads have a 55° angle in this case. BSP threaded fittings are less common than NPT threaded fittings in the oil and gas industry

NPT Fittings

NPT stands for “National Pipe Tapered” and is the dominant standard for threaded forged fittings in the oil and gas industry. NPT threading is covered by the ASME B1.20.1 specification and is based on 60° thread flank angles (vs. 55° of the BSP type).

FORGED FITTINGS MATERIALS

Carbon steel fittings ASTM A105 (forged)

A105 socket weld and threaded fittings match carbon steel pipes for high-temperature services, like ASTM A53, A106 and API 5L. For low-temperature service, ASTM A350 socket/threaded fittings shall be used instead (to match ASTM A333 pipes).

A105 Forged Fittings Materials, Chemical Composition %Show 10202550100 entriesSearch:

| Material Grade | Grade or Class | C | Si | Mn | S | P | Cu | Ni | Cr | Mo | V | Cb/Nb |

|---|

| ASTM A105 | 0.35 | 0.10-0.35 | 0.60-1.05 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | ||

| ASTM A181 | 60 | 0.35 | 0.10-0.35 | 1.1 | 0.05 | 0.05 | ||||||

| 70 | 0.35 | 0.10-0.35 | 1.1 | 0.05 | 0.05 | |||||||

| ASTM A266 | 1 | 0.3 | 0.15-0.35 | 0.40-1.05 | 0.025 | 0.025 | ||||||

| 2 | 0.3 | 0.15-0.35 | 0.40-1.05 | 0.025 | 0.025 | |||||||

| 3 | 0.35 | 0.15-0.35 | 0.80-1.35 | 0.025 | 0.025 | |||||||

| 4 | 0.3 | 0.15-0.35 | 0.80-1.35 | 0.025 | 0.025 | |||||||

| ASTM A350 | LF1 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 |

| LF2-1 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 | |

| LF2-2 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 | |

| LF3-1 | 0.2 | 0.20-0.35 | 0.9 | 0.04 | 0.035 | 0.4 | 3.30-3.70 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF3-2 | 0.2 | 0.20-0.35 | 0.9 | 0.04 | 0.035 | 0.4 | 3.30-3.70 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF5-1 | 0.3 | 0.20-0.35 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 1.00-2.00 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF5-2 | 0.3 | 0.20-0.35 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 1.00-2.00 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF6-1 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF6-2 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF6-3 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF9 | 0.2 | 0.40-1.06 | 0.04 | 0.035 | 0.75-1.25 | 1.60-2.24 | 0.3 | 0.12 | 0.03 | 0.02 | ||

| LF787-2 | 0.07 | 0.4 | 0.40-0.70 | 0.025 | 0.025 | 1.00-1.30 | 0.70-1.00 | 0.60-0.90 | 0.15-0.25 | 0.03 | 0.02 min | |

| LF787-3 | 0.07 | 0.4 | 0.40-0.70 | 0.025 | 0.025 | 1.00-1.30 | 0.70-1.00 | 0.60-0.90 | 0.15-0.25 | 0.03 | 0.02 min |

Showing 1 to 20 of 20 entriesPreviousNext

A105 Forged Fittings, Mechanical PropertiesShow 10202550100 entriesSearch:

| Material Grade | Grade or Class | Tensile Strength min, Ksi | Yield Strength Ksi @ 0.2% | Elongation in 2 in, % |

|---|

| ASTM A105 | 70 | 36 | 22 | |

| ASTM A181 | 60 | 60 | 30 | 22 |

| 70 | 70 | 36 | 18 | |

| ASTM A266 | 1 | 60-85 | 30 | 23 |

| 2 | 70-95 | 36 | 20 | |

| 3 | 70-95 | 36 | 20 | |

| 4 | 75-100 | 37.5 | 19 | |

| ASTM A350 | LF1 | 60-85 | 30 | 25 |

| LF2-1 | 70-95 | 36 | 22 | |

| LF2-2 | 70-95 | 36 | 22 | |

| LF3-1 | 70-95 | 37.5 | 22 | |

| LF3-2 | 70-95 | 37.5 | 22 | |

| LF5-1 | 60-85 | 30 | 25 | |

| LF5-2 | 70-95 | 37.5 | 22 | |

| LF6-1 | 66-91 | 52 | 22 | |

| LF6-2 | 75-100 | 60 | 20 | |

| LF6-3 | 75-100 | 60 | 20 | |

| LF9 | 63-88 | 46 | 25 | |

| LF787-2 | 65-85 | 55 | 20 | |

| LF787-3 | 75-95 | 65 | 20 |

Showing 1 to 20 of 20 entriesPreviousNext

Low-alloy steel fittings ASTM A182 (forged)

Low-alloy forged fittings match chrome-moly pipes ASTM A335 in grades P5 (for F5 fitting), P9 (for F9 fitting), P11 (for F11 fitting), P22 (for F22 fitting), P91 (for F91 fittings). The chemical composition of these common alloy grades for socket weld and threaded fittings is shown below:

| Low-Alloy Forged Fittings Materials | A182 F5 | A182 F9 | A182 F11 | A182 F22 | A182 F91 |

| C | 0.15 Max | 0.15 Max | 0.10-0.20 (2) | 0.05-0.15 | 0.08-0.12 |

| Mn | 0.30-0.60 | 0.30-0.60 | 0.40-0.65 | 0.30-0.60 | 0.30-0.60 |

| P | 0.035 Max | 0.030 Max | 0.025 Max | 0.035 Max | 0.020 Max |

| S | 0.030 Max | 0.030 Max | 0.040 Max | 0.040 Max | 0.010 Max |

| Si | 0.50 Max | 0.50-1.00 | 0.50-0.80 | 0.50 Max | 0.20-0.50 |

| Ni | 0.50 Max | – | – | 0.40 Max | |

| Cr | 4.0-6.0 | 8.0-10.0 | 1.00-1.50 | 2.00-2.50 | 8.0-9.5 |

| Mo | 0.44-0.65 | 0.90-1.10 | 0.44-0.65 | 0.90-1.10 | 0.85-1.05 |

| V | – | – | – | 0.18-0.25 | |

| Cu | – | – | – | – | |

| Other | – | – | – | Cb, 0.06-0.10; N, 0.03-0.07; Al, 0.04 max. |

Stainless steel fittings ASTM A182 (forged)

Stainless steel forged fittings match ASTM A312 pipes. The chemical composition of stainless steel socket weld and threaded fittings is given below:

| ASTM A182 Forged Fittings Materials in % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A182 Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Nb | Ti | Others |

| F304(1) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-13.0 | 18.0-20.0 | ||||

| F304N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F304LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F309H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 12.0-15.0 | 22.0-24.0 | ||||

| F310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310MoLN | 0.030 | 2.0 | 0.030 | 0.015 | 0.40 | 21.0-23.0 | 24.0-26.0 | 2.0-3.0 | N 0.10-0.16 | ||

| F316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316Ti | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | (3) | N 0.10 max | |

| F317 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F317L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (4) | |||

| F321H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (5) | |||

| F347 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | |||

| F347H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | |||

| F348 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | Co 0.20 Ta 0.10 | ||

| F348H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | Co 0.20 Ta 0.10 |

Socket weld fittings are available, also, in other grades as duplex and super duplex (ASTM A182 F51, F53/F55) and various nickel-alloys (Inconel, Incoloy, Monel, Hastelloy).